Handmade pipes have been crafted by artisans for centuries, originally using materials like clay, stone, and wood. While factories mass produce pipes today, many pipe makers still create them by hand as an artform. The process involves shaping the pipe material, hollowing out the bowl and shank, decorating the exterior, and finishing the pipe so it can be properly smoked.

Making a handmade pipe requires patience, practice, and a few key materials. You’ll need a block of briar wood, the preferred material for quality handmade pipes thanks to its heat resistance. Hardwoods like olivewood can also be used. Carving tools like files and knives shape the briar, while a hand drill or power drill bores the tobacco chamber. Sandpaper smoothes and polishes the pipe once carved. Additional tools are used for decorative elements like acrylic stems and metal bands around the shank.

With some creativity and carpentry skill, you can craft an attractive, durable, and satisfying pipe by hand. This process provides an enjoyable hobby for pipe enthusiasts as well as artisanal pipe makers.

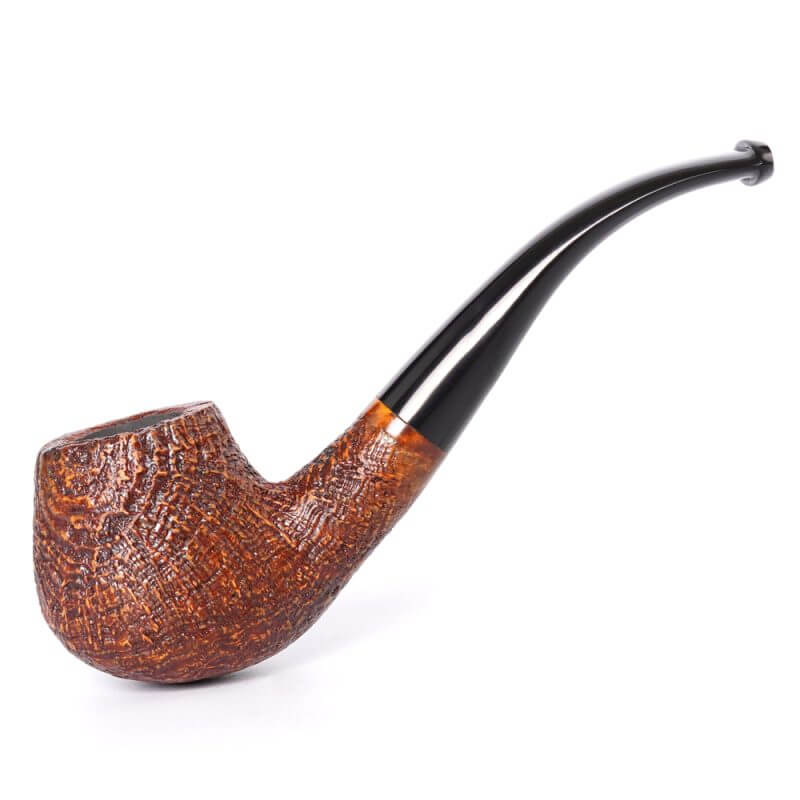

Artisan-Carved Holmes Tobacco Pipe

Handmade Lord Of The Rings Gandalf Pipe

Wooden Sandblasted Gandalf Pipe

English Classic Hobbit Style Churchwarden Pipe

Can I use any wood to make a pipe?

When making a handmade pipe, it’s important to select the right materials to ensure a safe and durable finished product. The best material for handmade pipes is typically a hardwood like cherry, maple, olive, or briar. Hardwoods are naturally dense and can withstand repeated heating without releasing any chemicals. They also polish to a smooth finish and impart little flavor on the smoke.

Some key tips on selecting materials:

Stick to untreated, unfinished hardwoods. Avoid any woods that have been stained, painted, or chemically treated, as these can release toxic substances when burned.

Avoid softwoods like pine or cedar as they burn too easily. Also avoid composite boards or plywood.

Choose a food-safe wood that won’t impart any unpleasant flavors. Fruitwoods like cherry, apple, or olive are ideal. Stay away from woods like redwood or eucalyptus that can make the smoke taste bitter.

Shaping the Pipe

Once you have selected your wood block, the next step is to shape it into the form of your pipe. This involves cutting the basic shape, drilling the bore hole through the center, and refining the shape with files and sandpaper.

First, use a bandsaw or handsaw to cut the wood into the rough outline of the pipe bowl and shank. Cut away any large chunks of excess wood, but leave extra material for now.

Next, drill the bore hole through the center of the pipe using a drill press or hand drill. Use a drill bit that matches the diameter you want for the pipe’s hollow airway. Drill slowly to avoid cracking the wood. Drill from both ends to meet in the middle.

Now you can begin shaping the external form of the pipe with files and sandpaper. Carefully file away excess material to refine the shape. Create smooth, rounded edges and symmetrical lines. Use coarse sandpaper to rapidly remove wood, then switch to finer grits for a smooth finish. Target any rough spots and blend all the edges.

Check the pipe’s balance by holding it in your hand as you shape it. Sand the entire outer surface to remove file marks and achieve a uniform smoothness. The general shaping process involves removing wood slowly and carefully to uncover the pipe form within the block. Take your time – don’t rush this important step or you may make a mistake and have to start over.

Inlaying Other Materials

Inlay involves cutting gaps into the pipe surface and filling them with decorative materials like wood, stone, antlers, gems, crushed stone, glitter, etc. Cut inlay channels to the exact width needed for your inlay material to sit flush with the pipe surface. Carefully glue inlays in place with cyanoacrylate adhesive before sanding and polishing. The contrasting colors and textures make inlays r

Carving Designs

You can carve designs directly into the surface of your pipe using knives, gouges, or specialty carving tools. Consider carving textures, patterns, shapes, logos, symbols, words, or anything else that reflects your unique style. Take your time carving to avoid mistakes. Seal carved areas well so smoke doesn’t accumulate in the grooves

Get creative with the decorations and make your pipe truly one-of-a-kind. Consider combining techniques like carving and inlay for additional visual interest.

Bore Hole and Shank

The bore hole is the hollow air channel that runs through the center of the pipe stem and bowl. This is what allows smoke to travel from the burning tobacco down through the shank and into the mouthpiece. Proper drilling is crucial for airflow and smoking performance.

When drilling the bore hole, work slowly and carefully. Use a drill press if possible for best results. Clamp the block tightly and center the drill bit over the marked location. Start with a small pilot hole using a 1/8 inch bit. Go slowly to avoid cracking the wood. Gradually increase the bit size in 1/16 inch increments until reaching the desired diameter, usually 5/32 to 3/8 inch. Make sure to drill straight through the center.

Smooth and polish the inside of the bore hole with fine grit sandpaper wrapped around a dowel. Check for smoothness by blowing air through. The goal is an even channel free of debris or imperfections which could disrupt airflow.

The shank is the end section that connects the bowl to the stem/mouthpiece. This can be carved directly out of the same block of wood. Or, a separate pre-drilled shank can be fashioned and attached. Ensure the bore hole lines up precisely when joining the shank to the bowl.

Friction fit is common for joining the shank and stem. The parts are sanded until the tenon slides smoothly into the mortise. A tight press fit keeps them securely together while still allowing disassembly for cleaning. Adhesives or wraps can also be used. Proper alignment is key for smooth airflow through the finished pipe.

Take great care when drilling, sanding and polishing the shank and bore hole. A straight, obstruction-free air channel is critical for an enjoyable, properly functioning handmade smoking pipe.

Sanding and Polishing

Once the pipe is shaped, it must be sanded smooth and polished to a clean finish. Start with a coarse grit sandpaper like 80 or 100 to remove any rough edges and shape imperfections. Gradually use finer grits like 150, 220, 400, and 600 for a smoother surface.

For an extra polished finish, use polishing compounds. Apply a medium polish first by rubbing a cotton cloth into the compound and polishing the pipe surface. Use a fine polish afterwards repeating with a clean cotton cloth. Rotate the pipe as you polish to ensure even coverage. Take extra care when polishing curved surfaces.

The compounds fill in tiny scratches and make the surface shine. Follow any instructions from the polishing compound manufacturer. Be sure to thoroughly clean the pipe afterwards to remove any excess polish residue.